Understanding the Features of WPC Core

Wood Plastic Composite Core (WPC Core) is a cutting-edge material that combines the best qualities of both wood and plastic. These include 30% high-density polyethylene (HDPE), 60% wood fiber and 10% Additives. The distinct blending makes a product that not only looks and feels like wood but also provides superior durability and stability. Its high density imparts firmness to give WPC Core the ability to withstand wear and tear from the environment (UV rays and temperature from -30 to 60 degrees Celsius).

Ease of installation and low labor costs are two of the top benefits of WPC Core. The maintenance is minimal, regular cleaning is all it requires to retain its looks and there is no painting or gluing involved. Plus, WPC Core is 100% recyclable which adds to its environmental sustainability value and conservation of forest resources!

Comparing WPC Core and SPC Core

Material Differences Between WPC and SPC Cores

WPC (Wood Plastic Composite) and SPC (Stone Plastic Composite) cores are suitable for the same applications on floors, but the material contents of WPC and SPC cores are very different. WPC consists of a polymer-based matrix, a floor-allocated wood fiber felt, yielding lower unit weight and impact sound absorption which results in a relatively softer underfoot. Unlike SPC that is mainly limestone powder blended with stabilizers to produce a more compact and firm core, providing better impact resistance.

Performance Comparison in Various Conditions

WPC Core is also really lightweight and uses an expanded polymer core to provide comfort and perform well under different conditions. It’s excellent at concealing minor subfloor imperfections and provides maximum protection from household spills and humidity. SPC Core — SPC Core’s rigidity, on the other hand, makes it a better choice for heavy foot traffic areas where sturdiness is key. Both offer excellent weather resistance, but the choice between the two depends on the type of user, as the materials are very different by nature.

Integrating WPC Core with Other Technologies

Enhancing with UV Coating

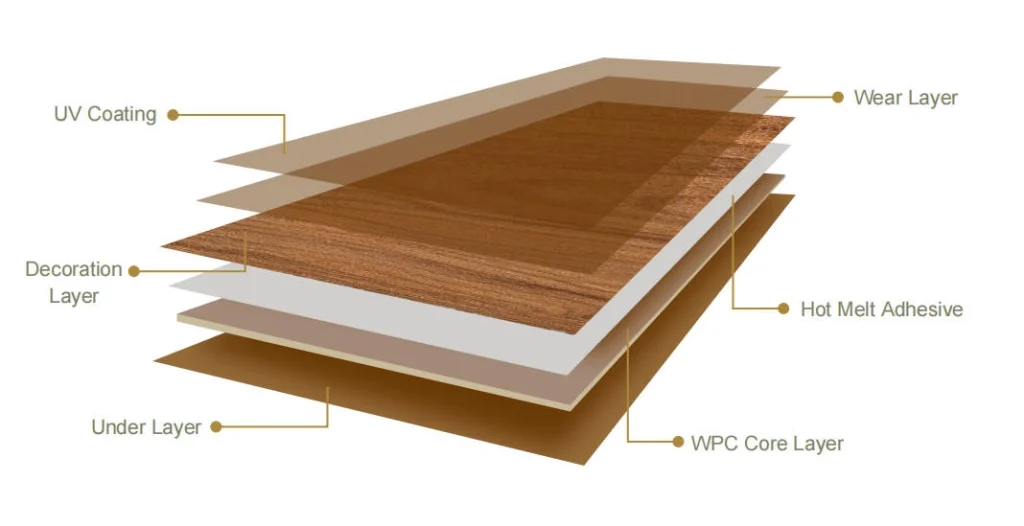

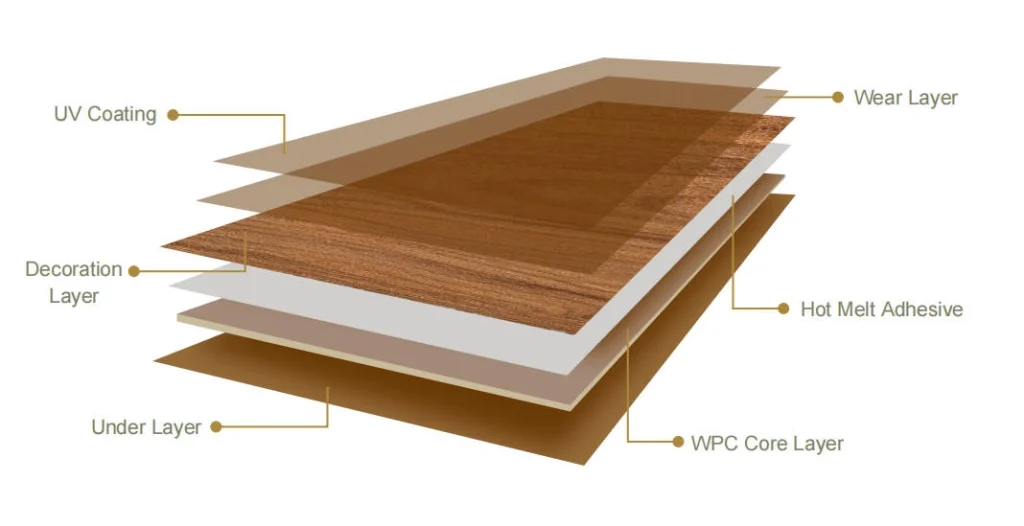

One such technology is UV coating, which gives WPC Core an added layer of surface protection from fading due to exposure to sunlight. This coating helps maintain color quality long after the initial installation and gives scratch resistance to the flooring so that it looks fresh and new every day. The durable coating preserves the color over the years and provides a scratch-resistant surface that keeps the floor looking new despite regular wear and tear.

Adding Wear Layers for Increased Resilience

The most important layer is the wear layer because it improves the longevity of your WPC flooring, making it resistant to scratches, dents, and stains. These are coatings applied in layers that protect the ornamental surface without detracting from wood or stone finishes. With the use of wear layers in the design, the manufacturers can ensure that the product stays effective with durability without any compromise on looks and appearance.

Incorporating Decorative Layers for Aesthetic Appeal

The decorative layer in WPC flooring is crucial to mimicking the appearance of real materials such as hardwood or slate. Depicts realistic textures and patterns with advanced printing techniques that beautify spaces. Available in numerous styles, users can select designs that complement their interior decor style while also enjoying the practical benefits WPC Core provides.

Utilizing Noise Reduction Layers for Acoustic Efficiency

Noise reduction layers, improvements that have been made on WPC flooring systems, aim to alter the faux acoustic efficiency of residential or commercial environments. They effectively absorb sound vibrations and reduce noise transmission between floors, which is an especially advantageous aspect in multi-story buildings or busy office environments, where minimizing noise pollution is crucial for comfort and productivity.

Applications of WPC Core in Various Industries

Use of WPC Core in Flooring Solutions

Residential Flooring Options

WPC Core, with its unmatched beauty, resiliency along ease of installation, has emerged as a perfect choice for residential flooring. WPC flooring boasts an attractive wood-like look that complements their interiors with a high proportion and homeowners appreciate this factor significantly. This click-lock system makes for an easy installation even the most inexperienced DIYer can get professional results without using a single nail or drop of glue. Its moisture resistance also makes it suitable for moisture-active rooms, such as kitchens and bathrooms.

Commercial Flooring Installations

In the commercial place, WPC Core is a perfect choice that stands to heavy foot traffic. Featuring a built-out polymer structure, it has great acoustical properties, making the product quiet in active places such as offices and retail locations. Another compelling benefit for businesses is its relatively low maintenance, which equals lower downtime and lower maintenance costs. WPC flooring is also available in so many style and finish options that they can match any corporate branding and even any corporate office interior design scheme.

Implementation of WPC Wall Panels

Interior Design Applications

Due to its versatility and aesthetic pleasing, WPC wall panels are gaining popularity as an interior design. These panels serve as a contemporary option to ordinary wood paneling while achieving a natural appearance without maintenance headaches. They are convenient to set up and clean which makes them appropriate for both home and workplace interiors. WPC wall panels offer durability and resistance against environmental factors, These characteristics help different designers design feature walls by adding texture and depth to spaces.

Exterior Cladding Uses

Exterior Applications WPC wall panels are efficient cladding material that has high aesthetic appeal as well as functional benefits. The weather resistance ensures durability for all seasons and protects buildings from moisture infiltration and UV damage. This means that they are perfect for facades and other structures that require both aesthetic and performance qualities in exterior settings. Affordability however does not come without a cost, WPC materials are very eco-friendly and appeal to institutions via sustainable building practices.

Adoption of WPC Tiles in Construction Projects

Owing to their practicality, versatility, and space-saving utility, WPC tiles are increasingly becoming the go-to option for different types of construction ideas. This is a common thing to use these tiles in outdoor areas and patios, balconies, and walkways where you can have a catchy and long-lasting surface as well. Its interlocking design means speedy on-site assembly free of any specialized tools or skills necessary. They also embody a slip-resistant nature which allows them to be used in wet areas so that they can act as poolside or garden paths.

Latitude High-Quality WPC Products Offerings

Commitment to Environmental Sustainability

Latitude products use environmentally friendly materials, do not contain heavy metals, and are rated as ENF grade material. It is beneficial for promoting development while ensuring the safety of the usage environment. By doing so, Latitude not only contributes to environmental protection but also responds to the increasing consumer demand for environmentally friendly building materials.

Customization Options for Diverse Needs

Latitude includes an extensive set of customization options to help fit the needs of clients in different industry verticals. Custom flooring designs or wall panels, price and texture, and color that fit your project. This makes Latitude’s WPC products able to receive continual adaptation while upholding high performance in any design.